Signs Your Packaging Machine Requirements Immediate Repair

Signs Your Packaging Machine Requirements Immediate Repair

Blog Article

Effective Ways to Troubleshoot Common Issues in Product Packaging Machine Operation

In the realm of manufacturing and production, guaranteeing the smooth procedure of packaging devices is vital to keeping performance and meeting deadlines. Even the most advanced devices are not immune to encountering usual concerns that can interfere with the whole manufacturing process. Taking care of these difficulties promptly and successfully is vital to reducing downtime and maximizing outcome. By implementing an organized approach to troubleshooting and preemptive upkeep, operators can not only address problems quickly yet additionally protect against possible obstacles in the future. Allow's discover some effective strategies that can help in swiftly settling typical problems in product packaging maker procedure.

Identifying Common Product Packaging Maker Issues

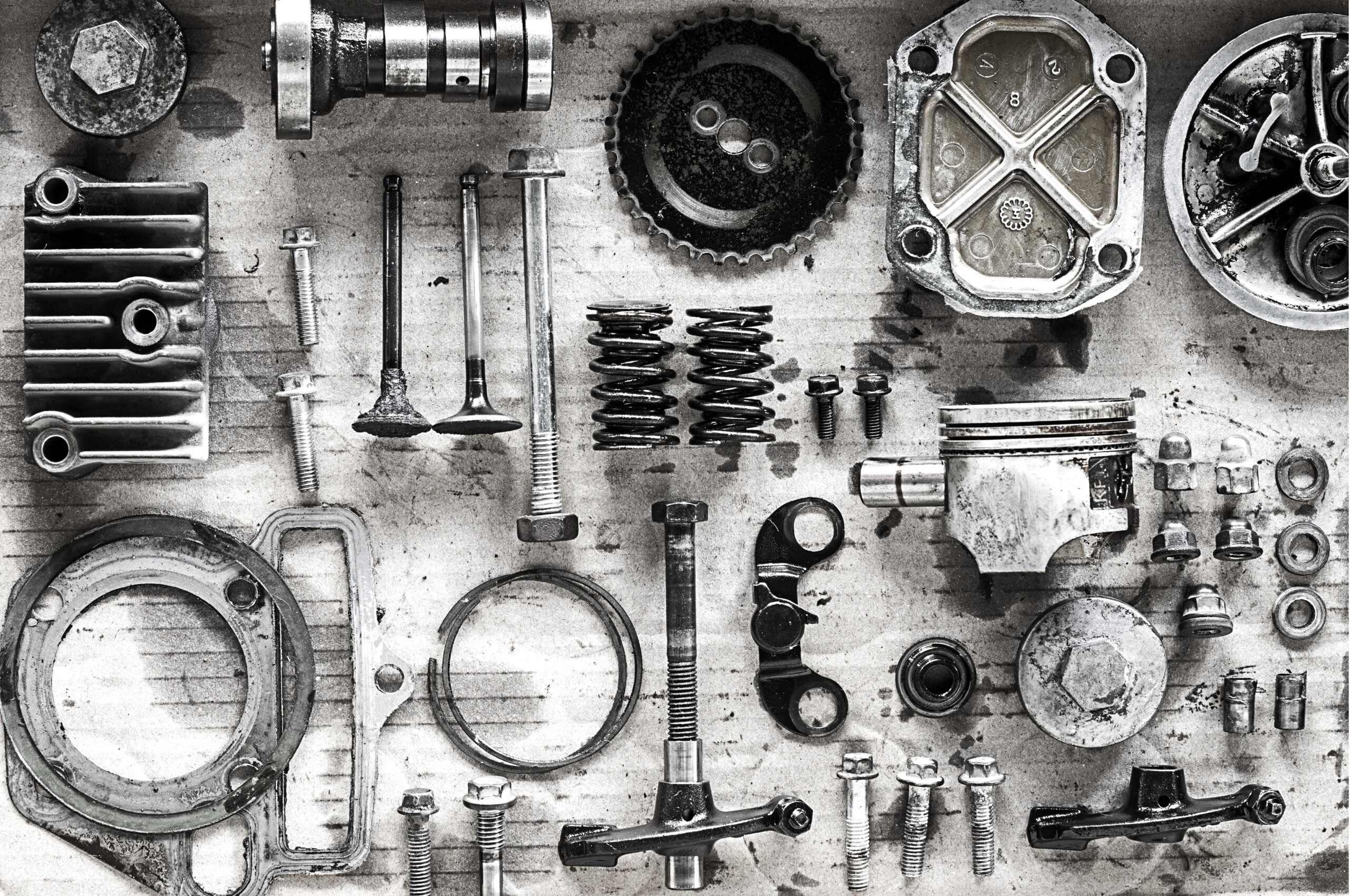

When fixing product packaging maker issues, it is crucial to accurately determine usual issues that may occur during the product packaging process. One common problem run into in packaging devices is improper sealing. This can cause items not being firmly packaged, taking the chance of damages or contamination during transportation. Another frequent issue is imbalance, where the product packaging products or items are not correctly aligned, creating jams or misfeeds. In addition, mechanical wear and tear on elements like belts, chains, or gears can result in inconsistent packaging or machine breakdowns.

Electric problems, such as defective wiring or power supply concerns, are also common wrongdoers behind packaging machine failures. By identifying these issues early on, drivers can avoid downtime, minimize item waste, and make certain the smooth performance of packaging machinery.

Doing Regular Upkeep Checks

On a regular basis conducting comprehensive upkeep checks is crucial for making sure the optimal efficiency and longevity of product packaging makers. Furthermore, checking and calibrating setups associated to stress, speed, and temperature can assist maintain the maker's efficiency and precision.

In addition, conducting normal examinations of electric connections and controls can help stop electrical breakdowns and make certain the safety of the equipment drivers. Documenting maintenance tasks and keeping detailed records of parts substitutes and repair work can help in tracking the equipment's efficiency with time and determining any type of reoccuring problems. Eventually, a positive method to regular upkeep checks is vital in taking full advantage of the productivity and integrity of product packaging equipments.

Repairing Mechanical and electric Problems

Effective troubleshooting of mechanical and electrical problems in product packaging equipments requires a methodical approach and a deep understanding of the device's elements and procedure. When encountering electrical problems, start by checking power sources, connections, and control panels for any noticeable damages or loosened links. Using a multimeter can aid recognize electrical mistakes such as short circuits or open circuits. Additionally, examining sensors, actuators, and communicates for correct capability is important in diagnosing electrical malfunctions precisely.

On the mechanical front, troubles like jams, imbalances, or extreme vibrations can disrupt product packaging operations. To deal with mechanical concerns, conduct a thorough aesthetic inspection of moving components, belts, chains, and equipments for signs of wear or damages. Lubrication of crucial parts can prevent friction-related problems and ensure smooth equipment operation. Validating the placement of elements and adjusting tension where essential can correct concerns associated to imbalances or irregular activities in the packaging equipment. By combining a systematic method with a detailed understanding of the machine's operations, reliable troubleshooting of electric and mechanical problems can be attained, reducing downtime and enhancing production result.

Optimizing Equipment Settings for Efficiency

To boost the total efficiency of packaging makers, a vital element entails fine-tuning and optimizing maker settings for optimal performance and outcome uniformity. Effectively adjusted equipment setups can considerably affect the speed, precision, and quality of the packaging process. One essential component to take into consideration is readjusting the equipment's speed settings to find the optimum balance between pop over to this web-site productivity and accuracy. By fine-tuning the rate, you can avoid concerns such as jams or misaligned packaging. Additionally, changing the stress setups, including the securing and cutting stress, is important for ensuring that packages are secured securely without damaging the products. Guaranteeing the proper temperature level setups for securing aspects such as warmth sealers or thermal transfer printers is additionally important to preserve the stability of the product packaging. Consistently checking and changing these device settings based on the specific requirements of the packaging products and item can cause boosted effectiveness, decreased downtime, and boosted general outcome quality.

Executing Preventive Upkeep Measures

Carrying out preventative maintenance actions is essential for making certain the longevity and ideal Get More Information efficiency of packaging makers in commercial setups. Routine upkeep aids prevent unexpected failures, decreases downtime, and eventually conserves money and time for companies. To successfully apply preventive maintenance, produce a thorough upkeep schedule outlining jobs such as cleansing, lubricating, inspecting, and replacing worn parts. This routine must be adhered to faithfully by experienced maintenance personnel to make certain that the makers run at peak performance.

In enhancement to arranged upkeep, it is important to maintain extensive documents of all maintenance activities done on the packaging makers. By focusing on preventative maintenance, services can prolong the lifespan of their packaging makers, lessen interruptions in production, and keep consistent item quality.

Conclusion

In verdict, reliable troubleshooting of usual concerns in product packaging machine operation involves identifying troubles, carrying out routine maintenance checks, troubleshooting electrical and mechanical issues, enhancing device settings for performance, and implementing precautionary maintenance actions. By adhering to these actions, drivers can make certain dependable and smooth procedure of packaging devices, reducing downtime and taking full advantage of productivity.

When troubleshooting packaging equipment issues, it is essential to precisely identify common concerns that might occur throughout the packaging process.Efficient troubleshooting of electrical and mechanical issues in packaging devices calls for an organized method and more a deep understanding of the machine's parts and operation.To boost the overall efficiency of packaging equipments, an essential element entails fine-tuning and optimizing machine settings for optimal efficiency and outcome uniformity.Carrying out preventive maintenance procedures is critical for making certain the longevity and ideal efficiency of product packaging makers in industrial settings.In addition to arranged maintenance, it is crucial to keep detailed records of all maintenance tasks performed on the packaging makers.

Report this page